4 Ways To Improve The Environmental Protection Of Product Packaging

If packaging could talk, it might whisper, “I’m trying to be better.” Environmental protection is messy and—honestly—hard to define. From sourcing fibers and inks to assembly, freight, reuse and end-of-life, there’s no such thing as perfectly green. There’s only more responsible. Below are four practical ways I’ve seen brands (big and tiny) shift their boxes toward the greener side—without turning the unboxing joy into a guilt trip.

Table of Contents

1) Use renewable natural resources

Materials grown again (trees, cotton, bamboo, ag-waste fibers) give you a path to regeneration. Paperboard sourced from responsibly managed forests can be replenished over time, and mills keep improving fiber yield and water recovery. Biobased laminates and plant-derived coatings are also getting better each season—still not magic, but moving.

Real-world chatter: On forums, buyers often say packaging that looks obviously paper-based feels trustworthy and “less fussy.” A common theme is: if the box reads natural, consumers are more likely to recycle it and not feel bad about it. That soft behavioral nudge matters.

Helpful examples you can explore:

- Kraft looks and textures pair well with simpler shapes. See our kraft paper gift boxes and paper gift bags for inspiration.

- Cylindrical tubes can minimize waste on odd-shaped products; check paper tube packaging for formats and inserts.

- When you must ship rugged goods, fiber-first substrates still work—see printed corrugated boxes.

2) Use less material

Light-weighting is usually the biggest, quietest win. Smaller dielines, thinner boards where performance allows, fewer layers, fewer plastic windows. Less material → typically less energy and fewer process inputs across the lifecycle. Micro-optimizations stack: shaving 1–2 mm on a flap, removing an inner lid, switching to a one-piece mailer instead of a lid-and-base where feasible.

What I hear from ops folks and indie founders: once they reduce the number of box SKUs and “over-protection,” damages don’t spike like they feared. The psychological habit to over-cushion is real; testing breaks that bias.

Try formats that inherently sip materials:

- Slimmer folding cartons for retail.

- One-piece mailers and display-ready cardboard displays when shelf and ship share a box.

3) Reduce printing

Ink isn’t evil, just not a free lunch. Even with vegetable or water-based systems, more coverage means more inputs and more steps (prepress, washups, drying). Minimalist graphics, spot colors, smart negatives, and emboss/deboss textures can deliver brand wow without heavy coverage. Foils and special effects, used sparingly, can stay in the mix if you choose recyclable-friendly constructions and avoid plastic lamination where not needed.

User feedback patterns: people often say “clean and matte feels premium.” Minimal art also reduces scuff anxiety and improves perceived quality because small flaws don’t scream at you. Funny enough, less ink can make the product feel more expensive.

If you do need rich decoration, consider substrates designed to elevate simple marks—see printing services for finishes that work with low-ink layouts.

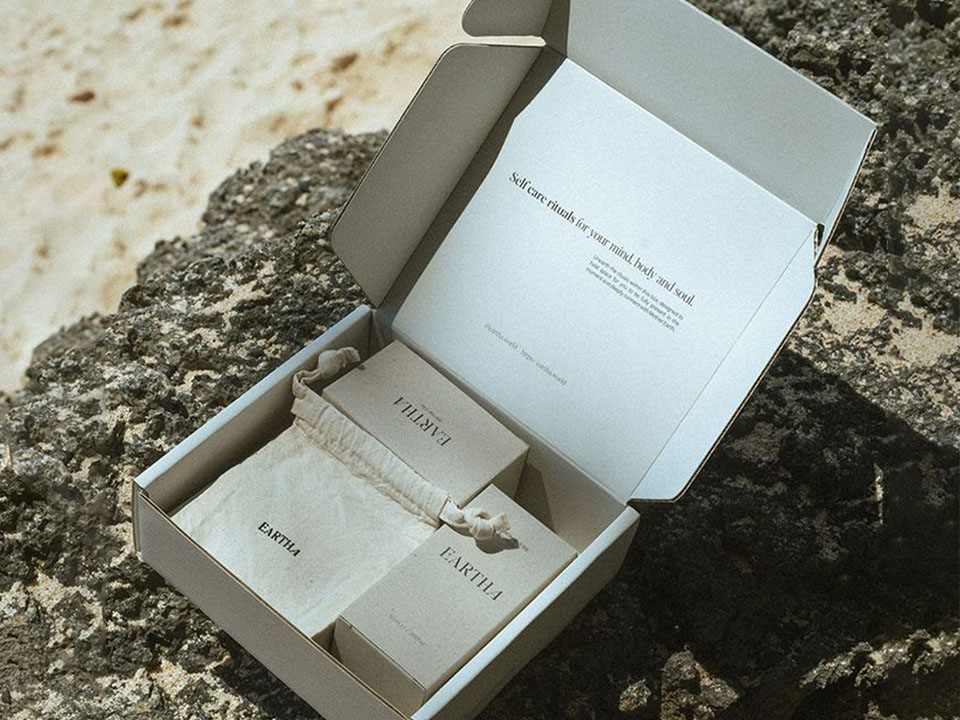

4) Make it reusable

If your audience will genuinely reuse a box (dresser storage, keepsakes, travel kits), then a sturdier construction can be the greener choice across its longer lifetime. That means hinging, magnets, trays, or textile touches that invite keeping—not tossing. But be honest: if the product category is fast-moving or the home is storage-tight, pushing reuse may just move the waste later.

Experience from buyers and reviewers: reusable done right becomes part of the product story (“I kept the candle box for my sewing kit”). Done wrong, it feels like clutter. A simple check—ask: Would I keep this in my own small apartment? If not, strip it back.

Explore premium but keepable builds:

- Durable rigid formats across products pages show options from drawers to clamshells.

- Security + longevity when required (e.g., regulated goods): see child-resistant packaging for compliant structures that still look giftable.

How to decide: a quick lifecycle sanity loop

- Map the trip: Raw materials → converting → printing → assembly → shipping → customer use → end-of-life.

- Cut weight first: Usually the highest-impact lever.

- Prefer fibers and mono-materials: Make it obvious how to recycle.

- Ditch “just in case” parts: Windows, trays, belly bands that don’t earn their keep.

- Design for recovery: Clear disposal cues; coatings that don’t break recycling.

- Test with real people: If they say “I’d keep this box,” reuse might be worth the added weight. If they say “I’ll flatten it,” steer minimalist.

##FAQ

Q1: Is paper always more eco than plastic? Not always; it depends on weight, distance, reuse, and local recycling. A heavy, laminated paper box that travels far can out-impact a lean plastic pouch in some cases. Context wins.

Q2: Are “eco inks” enough? They help, but coverage and processes matter more. Best move is fewer passes, fewer plates, more clever whitespace.

Q3: Will minimal packaging hurt the unboxing experience? Nope—if the structure fits the product, tactile papers and small moments (a pull-tab, a deboss seal) can delight without ink-heavy artwork.

Q4: What about regulations? Certain categories (cosmetics, cannabis, child-resistant) need specific features. You can still choose fiber-first builds and restrained graphics—see the gallery under child-resistant packaging for compliant yet elegant options.

Editor’s tiny notes

I’m not pretending this is easy. Sometimes your spec will say one thing and your heart says another. It’s ok to compromise—ship something better this quarter, then better again next. Also, sorry for the occasional typos here; real people write like this, and that’s alright 🙂

Internal resources you can browse next

- Home base: Zhibang Packaging

- Explore formats: products

- Fiber-first looks: kraft paper gift boxes, paper gift bags

- Lean shipping options: printed corrugated boxes, folding cartons

- Specialty tubes: paper tube packaging

- Retail storytelling: cardboard displays

- Print craftsmanship: printing services

Conclusion

Environmental protection in packaging isn’t a badge—it’s a practice. Use renewable resources where it truly helps, reduce material as a rule, calm the ink down, and design reuse only when people will actually reuse. No box will be absolutely green, but box by box, you can be greener—and that’s the honest way forward.