What Are The Common Raw Materials Of Packaging Gift Boxes?

Confession: I’m a gift box, and I dress for the occasion. Some days I’m crisp paperboard in a tux, other days I’m corrugated in a comfy hoodie. I’m here to protect your goodies, but also to look good doing it. I ain’t perfect—sometimes my corners wrinkle a bit—but I try my best.

A deep, practical guide to common gift-box materials—paperboard, corrugated, specialty papers, wood, leather, plastic, and metal—with real user insights, print/finish tips, and examples for wine, mooncake, health-care, and electronics packaging.

The Big Material Families

Paper-Based

- White Card / SBS: Smooth, premium, excellent for printing. Often the outer wrap on a rigid set-up box.

- Greyboard / Chipboard: The hidden core that gives a rigid box its shape; usually wrapped with art paper or fancy paper.

- Coated Art Paper (gloss or matte): Vivid CMYK prints, spot colors, soft-touch films—your brand sings here.

- Kraft Paper: Natural vibe, tough fibers, fits earthy or eco-forward branding.

- Specialty “Fancy” Papers: Linen, pearl, embossed, soft-touch, holographic, even metalized effects for shine.

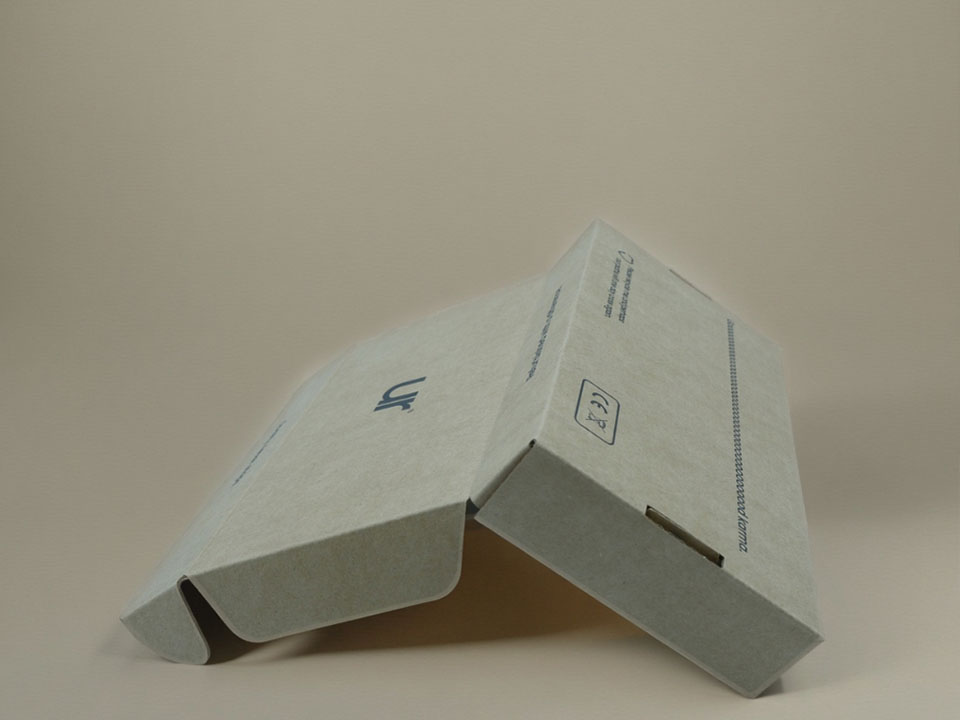

- Corrugated (E/F/B flutes): When you need cushion and crush strength—great for mailers or heavier gifts.

Try styles like a magnetic-closure gift box for cosmetics (example) or a rigid paperboard watch box (example). For confections, a chocolate gift box with insert keeps pieces snug (example). You can also browse our full product range for more formats and finishes (products).

Wood

Wood instantly reads premium. It’s durable, reusable, and loved for limited editions. Consider it for high-value wines/spirits or collectible sets where “keep me” matters.

Leather / PU Leather

Real leather feels luxe; PU leather offers color control and consistent texture. Think watches, jewelry, VIP kits. Drawer structures with velvet lining elevate the reveal.

Plastics

Clear windows to show product, thermoformed trays for precision fit, or clamshells for impact resistance. Use when clarity or exact positioning is critical. (Many users prefer easy-to-recycle setups—design for simple separation of materials.)

Metals

Rigid tins for tea, cookies, candles—durable, protective, and very giftable. The “clink” when you open it? Feels special.

Quick Comparison Table

| Material | Look & Feel | Best For | Typical Extras |

|---|---|---|---|

| Paperboard (rigid) | Premium, printable | Luxury gifts, cosmetics, jewelry | Foil, emboss/deboss, magnets |

| Corrugated | Protective, ship-ready | Heavier items, mailers | Die-cuts, inserts, inside print |

| Fancy Papers | Tactile & visual pop | Seasonal, beauty, premium | Soft-touch, textures, pearlescent |

| Wood | Heirloom | Limited editions | Engrave, inlaid logos |

| Leather / PU | Couture vibe | Watches, jewelry, VIP | Stitching, velvet lining |

| Plastic | Display clarity | Windows, exact-fit trays | Thermoformed inserts |

| Metal | Durable & reusable | Tea, cookies, candles | Embossed lids, airtight lids |

(Occassionally a mix works best—rigid box inside, corrugated mailer outside. Box-in-a-box. Very normal.)

Paper Substrates & Finishes

Common wraps:

- Coated art paper in the ~157–250 gsm range for rich print.

- Fancy papers (linen, soft-touch, pearl, holographic) for tactility.

- Kraft for natural tone.

Cores:

- Greyboard (chipboard) laminated to desired thickness for rigid set-up boxes.

- Micro-flute corrugated (E/F) for slim yet sturdy mailers and book-style boxes.

Printing: CMYK (4C) with optional spot colors for brand-critical hues.

Finishes: Gloss/matte lamination, soft-touch film, spot UV, emboss/deboss, hot foil (gold/silver/rose/blue), anti-counterfeit film, die-cut windows, hidden magnets, ribbon pulls. For jewelry and watches, consider EVA, sponge, or flocked blister inserts. For confectionery, food-safe trays are the norm. For tubes, see a round paper tube box option (example).

Material Picks by Gift Category

1) Wine Gift Boxes

- Structure: Rigid paperboard or E-flute corrugated with art-paper wrap.

- Print/Finish: CMYK + spot color; foil on brand marks; optional local UV.

- Insert: EVA, molded pulp, or die-cut corrugated for bottle stability.

- Why: Premium feel outside, shock resistance inside.

2) Mooncake Gift Boxes

- Structure: 157 gsm coated wrap over greyboard; alternate: cloth-texture or specialty papers.

- Finish: Foil (special gold/silver), embossing, soft-touch if needed.

- Inner: Food trays, sometimes sponge or flocked plastics for nests. Many boxes are still hand-finished for seasonal detail.

3) Health-Care Gift Boxes

- Structure: Rigid two-piece or book-style with partitions.

- Finish: Matte/gloss lamination, spot UV, foil, anti-counterfeit film if appropriate.

- Insert: Foam (model-type) with silk velvet cloth, or card partitions to keep vials upright.

4) Electronic Gift Boxes

- Structure: 157–210 gsm wraps on 800–1200 gsm cores, or micro-flute corrugated for shock resistance.

- Finish: Spot UV + foil on logo; magnets in flap; clean dielines.

- Insert: Thermoformed blister, EVA, or card cradles. A hexagonal electronics gift box can make it memorable (example).

5) Ordinary Mobile Phone Boxes

- Structure: 250–350 gsm SBS or grey back board; many brands frame with micro-flute (W9/B9/C9 pits) for strength.

- Finish: Minimalist outside, precise inserts inside for cables and manuals.

- Note: Book-style closures with two hidden magnets feel sleek and safe.

6) IT Electronic Products

- Structure: 250–300 gsm white card with micro-flute pits for crush strength.

- Finish: CMYK + spot, foil if needed; anti-counterfeit film optional.

- Insert: Pit paper or foam; design around the board’s protective bag and accessories.

7) General Electronics Packaging

- Structure: 250–300 gsm white card + micro-flute frame where needed.

- Finish: Clean CMYK, partial UV, optional foil.

- Insert: Paper tray, foam, or flocked blister depending on fragility.

What real users say

From community threads and long Q&As, a few patterns keep repeating (I’m paraphrasing real folks’ experiences, not quoting links):

- “Please, make it easy to open.” Over-packaging and plastic ties frustrate customers—clean tear strips and simple lids win.

- Recyclability matters. Many buyers say they prefer paper-first designs and minimal mixed materials. If there’s a window, make it easy to separate.

- Reusability = delight. A sturdy drawer box for jewelry often gets kept on the dresser; people love that second life.

- Scent & scuff issues. Users sometimes complain about foam off-gassing or coatings that scuff. Good suppliers test finishes and inserts together.

- Unboxing is part of the product. Magnetic closures, crisp edges, and tidy inserts make folks feel it’s premium—even when the product is small.

Want inspiration across jewelry, cosmetics, and more? See a slim sliding drawer jewelry box (example) or browse Zhibang Packaging for styles and sizing (our homepage).

Pro Tips from the Shop Floor

- Foil with restraint. Small foil accents beat giant foil rectangles (less cracking on edges).

- Soft-touch + spot UV is a classic luxe combo (matte skin, glossy logo).

- Mind the insert-first. Design the cradle (EVA, pulp, card) before you lock the outer size.

- Test closures. Magnet pull should match product weight; too strong feels annoying, too weak feels cheap.

- Pre-press matters. Rich black builds, overprint settings, and bleed on every edge—printer tears are real.

- For tubes, verify can height vs. product height and choose the right rolled edge so lids don’t “pop.”

- When in doubt, pick a reliable rigid structure and upgrade paper/finish—simple bones, nice jacket.

Internal Examples You Can Explore

- Zhibang Packaging (home): your starting point for all categories — homepage

- Browse the full product range — products

- Magnetic-closure gift box for cosmetics — view

- Rigid paperboard watch box (sleek unboxing) — view

- Chocolate gift box with insert (food-friendly nesting) — view

- Hexagonal electronics gift box (make it memorable) — view

- Sliding drawer jewelry box (keepsake factor) — view

- Round paper tube box (compact and cute) — view

FAQs

Q1: What’s the most common raw material for gift boxes? Paperboard (often greyboard core wrapped with coated or specialty paper). It balances print quality, rigidity, and a tidy unboxing.

Q2: Are plastic windows still ok? Yes—especially for display-heavy categories. Just design so the window can be removed easily if recycling is a priority.

Q3: Is metal too heavy for gifts? Not when the product fits the story (tea, cookies, candles). Tins are durable and feel collectible.

Q4: Corrugated or rigid board for electronics? Often both: a rigid inner for the reveal, a slim corrugated mailer for shipping. Box inside a box, no shame.

Q5: Do buyers actually care about packaging details? Oh yes. Based on many user discussions, people want clean opening, good protection, and a second life—or at least easy recycling. Fancy is fine, fussy not.

If you’re choosing between materials or need a fast recommendation, start at our homepage or explore the products library for real-world examples. And yes, my edges will be sharp—just don’t judge me if one corner folds a tiny bit; I’m only human… well, box-ish.