Quick Guide to Measuring Cosmetic Box Dimensions

If you sell skincare, makeup or perfume, your box size can make or break the whole project. The product has to fit snug, the design has to look sharp, and the shipping guys don’t want oversize cartons eating the freight budget. So getting cosmetic box dimensions right is not just “nice to have”, it’s basic survival.

At Zhibang Packaging, we work every day with beauty brands, OEM factories, e-commerce sellers, wholesalers and design studios to fix exactly this kind of headache.

This guide walks you through the essentials in a simple, hands-on way, with real use scenes you see in daily work.

Table of Contents

Why Accurate Cosmetic Box Dimensions Matter

Let’s start with the “why”. When your cosmetic box dimensions are correct, you get:

- Better product protection A face cream jar that can’t move around will survive long transit and warehouse life much better.

- Cleaner unboxing experience No rattling, no big gaps, no “why is this tiny bottle in a huge box?” questions from customers.

- Stable shelf display Retailers like boxes that face out nicely, line up on shelf, and don’t topple when someone touch it.

- Lower logistics and storage cost When your box uses the right cube, you fit more units per master carton, per pallet, per container.

- Smoother production Clear dimensions mean no back-and-forth with the printer, less re-sampling, less risk in mass run.

In short, measurement is step zero. Design, finish, fancy foil, all comes after.

How to Read L × W × H for Cosmetic Boxes

In packaging, we almost always write dimensions as L × W × H (length × width × height) in millimeters or inches.

- Length (L) – the longest side at the opening of the box.

- Width (W) – the shorter side at the opening.

- Height (H) – from the opening down to the base, the vertical depth.

Example scene:

You order a pink luxury cosmetic gift box for a skincare set. We write 230 × 170 × 80 mm. That means 230 is the long opening side, 170 is the short opening side, 80 is the height.

Most artwork, die-lines and production forms will follow this same logic. If one person flip width and length, the box still can be made, but it may not match your display idea.

Step-by-Step: How to Measure Cosmetic Box Dimensions

You don’t need be an engineer to measure correctly. Just follow this simple flow.

Measuring Your Cosmetic Product First

Before you even touch a box sample, measure the product:

- Put the bottle, jar or palette on a flat table.

- Use a ruler or tape to measure W × D × H of the product.

- Add a small clearance on each side (for example 2–4 mm) for easy loading and tolerance.

- If it’s a set, arrange products as you want them to sit in the box, then measure the overall block.

This gives us the minimum inner size of the box. At Zhibang we call this the “fit test” size.

A serum in a serum gift box with foam insert needs different clearance than a simple folding carton.

Measuring an Empty Cosmetic Box

When you already have a box sample in hand:

- Place the box upright on a flat surface.

- Open the top flap or lid.

- Measure inside length at the opening from left to right.

- Measure inside width at the opening from front to back.

- Measure inside height from opening edge down to the inner base.

- Repeat quickly to confirm numbers. Tiny differences can kill your tolerance.

Always write clearly “inside dimensions” on your drawing or email, so your supplier doesn’t guess.

Inside vs Outside Cosmetic Box Dimensions

This point sounds obvious, but many team still get it wrong the first time.

- Inside dimensions = the usable space where product and insert go.

- Outside dimensions = inside size plus the material thickness (board + wrap paper + lamination).

Why it matters:

- Your product engineer cares about inside dimensions.

- Your 3PL and freight forwarder care about outside dimensions (for shipping, pallet plan, storage).

- Your designer actually cares about both, because layout, window size and barcode placement depend on real panel sizes.

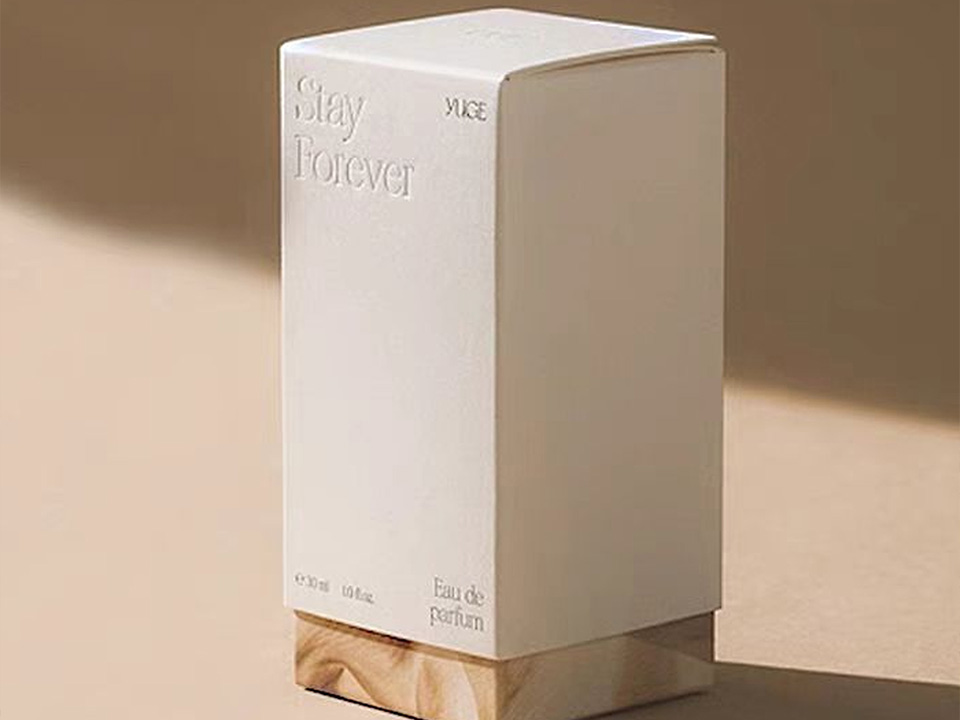

For a rigid magnetic cosmetic gift box, the board can be thick and wrapped. If you only check outside size, the inner tray might end up too tight for the bottle.

Typical Cosmetic Box Sizes by Product Type

Every brand is different, but there are common size ranges that show up again and again. Here is a simple reference table you can show to your team.

| Product type | Typical inner size (L × W × H) | Use scene example |

|---|---|---|

| Face cream jar | 60–80 × 60–80 × 60–90 mm | Single jar with simple cardboard insert |

| Serum bottle | 40–55 × 40–55 × 120–170 mm | One glass bottle with dropper, vertical pack |

| Lipstick / lip balm | 25–35 × 25–35 × 70–90 mm | Folding carton around plastic or metal tube |

| Eyeshadow palette | 90–150 × 60–120 × 15–25 mm | Flat palette in folding carton or rigid box |

| Sheet mask set | 120–180 × 20–40 × 180–230 mm | Multiple sachets in one paper gift box |

| Gift set / kit | 180–350 × 120–250 × 50–120 mm | Mix of bottles and jars in custom insert |

These are not fixed “standards”, but they give you a starting point. Once you know the rough range, we can fine tune for the actual bottles and trays.

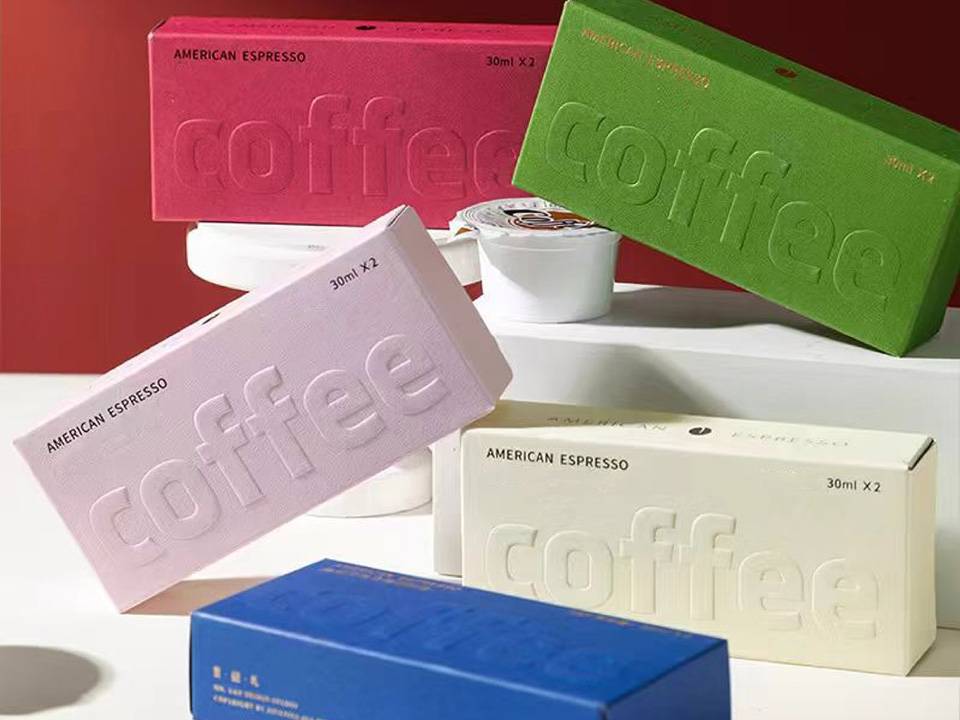

For simple cartons, you might use folding carton cosmetic packaging. For heavier sets or holiday launches, brands often move to rigid paper gift boxes with ribbon or magnetic closure.

Measuring Different Cosmetic Packaging Structures

Not every cosmetic box behaves same way when you measure:

- Folding cartons Used for everyday cosmetic boxes, perfumes, and skincare. You must consider glue flaps, crash-lock bottoms, hanger holes and windows on the die-line.

- Rigid lid and base boxes Great for heavy glass jars or premium sets. Height includes the shoulder and neck area, not just the tray.

- Magnetic rigid gift boxes These looks luxury, but the spine and magnet line eat space. If you don’t allow enough tolerance, the lid will not close flat.

- Paper tubes For oils or balms in paper tube packaging, you must match tube diameter to bottle diameter plus foam or paper collar.

- Corrugated mailer boxes For DTC or subscription shipment, the outside size is critical. Here we design the inner cosmetic pack first, then build an outer printed corrugated shipping box around it.

- Counter and floor displays If you use cardboard display stands, we measure each slot to match your box footprint, so the facing wall looks clean at retail.

In project talks we often build a quick “mock shelf” with dummy units just to see how these footprints play together.

Tools You Can Use to Measure Cosmetic Packaging

You don’t need fancy gadgets, but the right tools make life easier:

- Steel ruler or tape measure – fine for most carton and rigid box checks.

- Digital caliper – to check board thickness, insert wall, tube diameter with good precision.

- Large T-square or yardstick – helpful on large gift sets or display trays.

- Digital files – once we fix physical sizes, Zhibang can lock the die-line in CAD so your designer works on exact panels.

If you are measuring many SKUs, try to use the same set of tools each time, so your measurement style stays consistent.

Common Measurement Mistakes

Here are the classic pitfalls we see from brand teams and even some factories:

- Mixing units Part of the team uses inches, part uses millimeters. Somebody forgets to convert. Always decide one master unit.

- Measuring on a soft surface A bed, a stack of paper, even a soft mouse pad will bend the box slightly and change the number.

- Not saying inside or outside If you only write “box size 80 × 60 × 120 mm”, your supplier may guess wrong. Add “internal” or “external” clearly.

- Ignoring material thickness Especially for rigid boxes and tubes. When you upgrade to thicker board for a premium line, inner space shrink a bit.

- No tolerance talk In real production, paper and board will move slightly. You should agree a simple tolerance range with your supplier so your product still fit well even with small variation.

A quick internal SOP document for “how to measure cosmetic box dimensions” can already cut down half of these problems.

How Zhibang Helps You Get Cosmetic Box Dimensions Right

When you work with a custom shop like Zhibang, you don’t need to solve all dimension puzzles alone.

Here is how we normally support our beauty and personal care clients:

- Turn your rough size idea into a technical die-line and 3D drawing.

- Do a fit test using your real products, not just renderings.

- Recommend structure based on your channel: carton for mass retail, rigid for premium cosmetic boxes, corrugated for e-commerce, display for POS.

- Suggest proven structures like a pink rigid hair kit box, similar to our collapsible and magnetic gift boxes.

- Match your product to real cases, like a luxury cosmetic gift box or a rigid serum gift box.

We handle OEM/ODM, bulk orders and wholesale projects for brand owners, contract manufacturers, cross-border sellers, trading companies, gift houses and design agencies. If you need core lines like cosmetic boxes plus matching mailers and shippers, we can build a full SKU map so the sizes work together.

You can start from any hero SKU, send us the bottle or basic size, and we help build the rest of the box family around it. The goal is simple: everything fits, looks sharp, and moves smoothly from factory to customer.