Talk To Our Boss If You Didn't Find The Solution

Our boss, Alanna will ask our team to find out the solution very soon! You must be satisfied with our services!

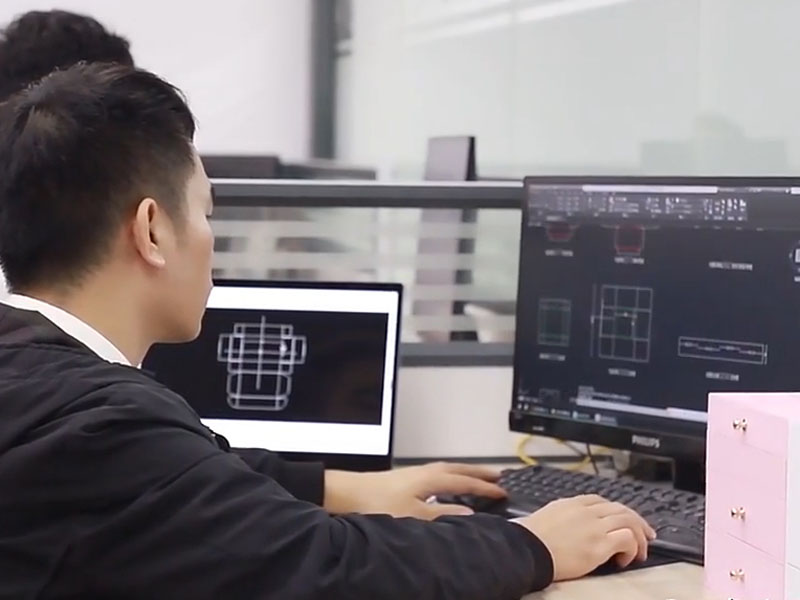

Work with one partner from the first structural idea to full-scale production. Our service model is built to make your packaging project faster, clearer and more predictable on cost and lead times.

A clear, step-by-step approach so you always know what’s happening next.

Whether you’re looking for a single hero box or a complete packaging system across multiple SKUs and markets, our team is ready to help. Share your product details, rough ideas or existing artwork, and we’ll come back with tailored structural and pricing options.