Balancing Cost vs. Branding in Custom Apparel Box Design

You already know the fight.

Finance wants to squeeze every cent out of the box.

Brand wants that slow, nice unboxing with a solid lid, soft-touch paper, maybe even a ribbon.

For apparel, the box is not just a container. It’s the first thing your buyer touches, both in-store and online. Some studies say around seven out of ten shoppers pay attention to how products are packed. Many people even share orders online when the packaging feels like a gift.

So your custom apparel box design is not decoration. It’s part of your P&L and part of your story. The trick is to let the box work for your brand, without letting cost run wild.

Below is a simple, more “shop floor” way to look at that balance.

Custom Apparel Box Design and Brand Perception

When someone gets a parcel at the door or walks out of a shop, they judge your brand in seconds. They notice color, board strength, how the lid opens, if the tissue lies nice or just looks messy. That tiny moment sets a value level in their head.

If the carton feels weak and noisy, your shirt feels cheaper.

If the box is heavy and over-done, some customers feel it’s wasteful.

A good custom apparel box design usually does three things at once:

- Shows your logo and key brand codes clearly.

- Protects the garment through the whole journey.

- Feels pleasant to open, not annoying.

Branded Apparel Packaging and Unboxing Experience

Unboxing is a real scene for fashion. People want to unfold, feel, maybe film or photo the moment. That’s why more brands move from plain mailers to proper branded apparel packaging:

- rigid shirt boxes with lids

- drawer-style boxes for underwear and socks

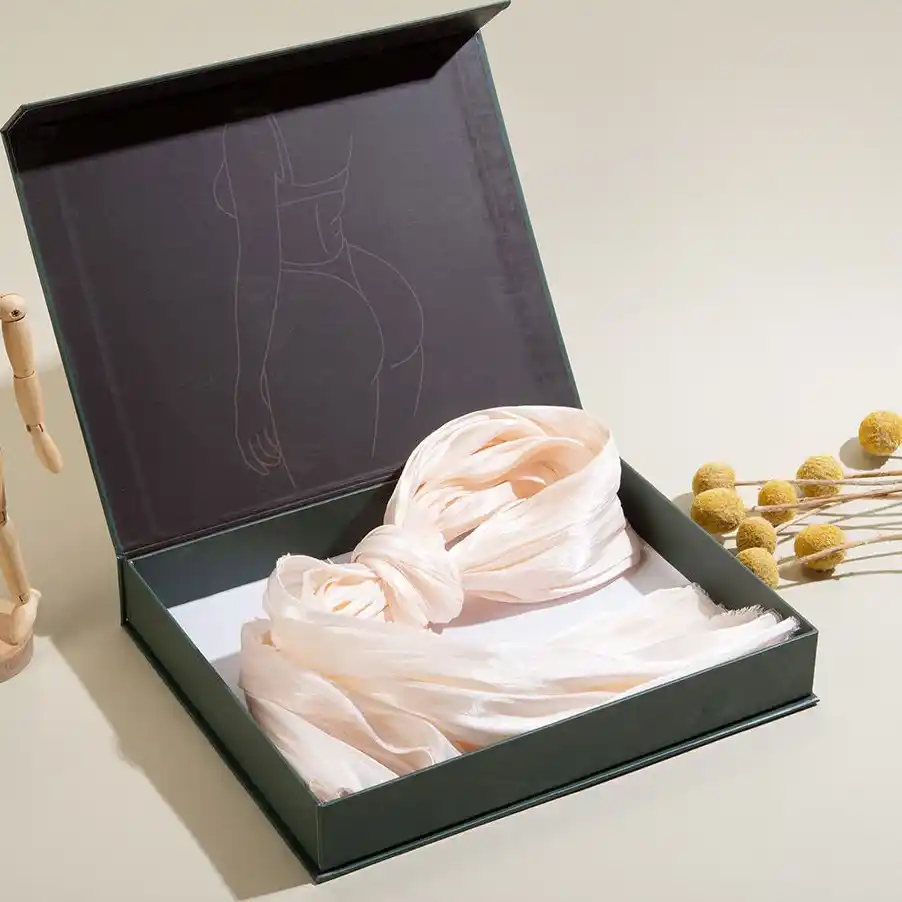

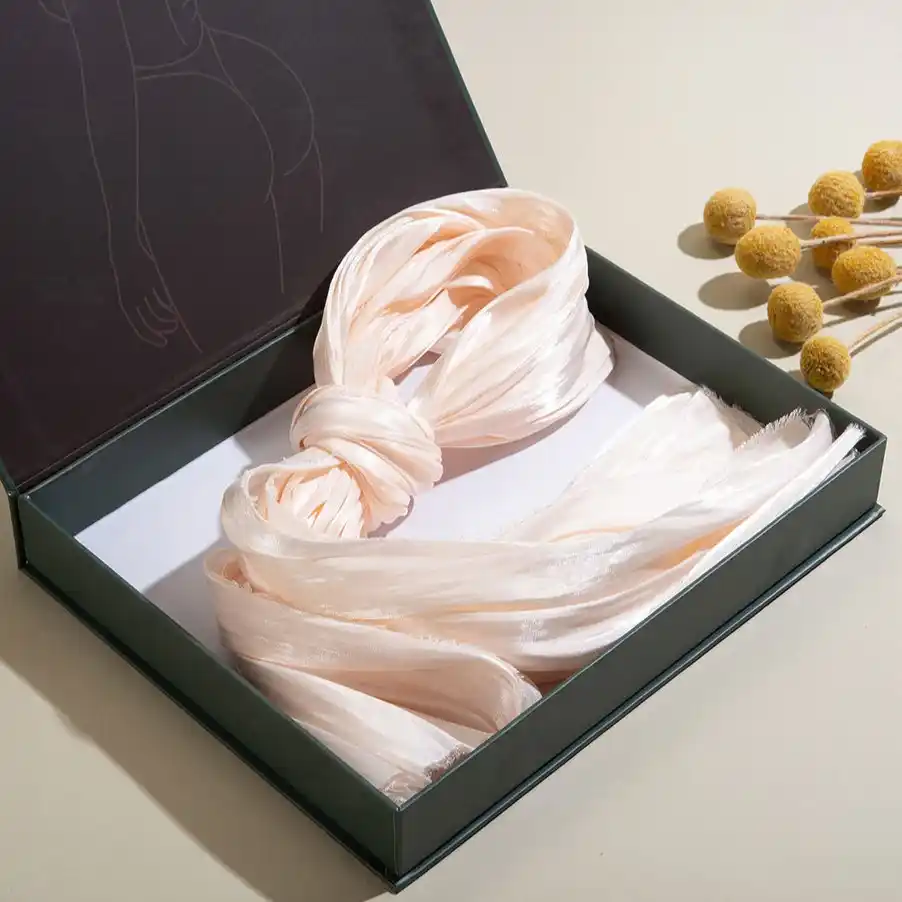

- magnet closure gift boxes for premium lines

If your line leans into gifting, you can go straight into formats like custom apparel gift boxes that already come with rigid structure, wrapped board and simple ribbon options.

To make it clearer, here’s a quick view.

| Packaging element | Typical shopper feeling | What it says about your brand |

|---|---|---|

| Clean print, strong box, neat fold lines | “This brand is serious, not random.” | You care about detail and long-term value. |

| Tissue, insert card, stable lid | “Feels like a present.” | You’re gifting-first, you value experience. |

| Eco paper, less plastic, easy to recycle | “Okay, they thought about the planet.” | You’re modern and responsible, not old-school wasteful. |

You don’t need a crazy luxury box for every T-shirt. But once people feel your pack once or twice, they start to remember you by the box, not just the logo.

Cost Control in Custom Apparel Box Manufacturing

Now the other side. You still need margin. To keep unit cost under control, you must break the box into parts, not just say “make it cheaper”.

In real production, apparel box cost mostly comes from:

- Board and paper – thickness, type, coating

- Printing and finishes – number of colors, foil, embossing, varnish, lamination

- Assembly and kitting – how much hand work, how many steps per box

- Freight and storage – how much air you ship, how many pallets you store

Once you see these buckets, you have levers you can actually pull.

Material Choices for Apparel Boxes and Folding Cartons

Most fashion brands play with three main structures:

- Rigid apparel boxes / gift boxes

- Folding cartons for clothing

- Printed corrugated shipping boxes / mailer boxes

Each has its own scene and cost behavior.

- Rigid lid-and-base or drawer boxes

- Best for shirts, jackets, knitwear, gift packs.

- Strong presence on shelf and in photos.

- More manual gluing, more touch points in the factory.

- You find them in ranges like paper gift boxes and dedicated apparel boxes.

- Folding cartons

- Great for basics, underwear, kidswear, multi-packs.

- Shipped flat, run fast on the line, easy to palletize.

- Perfect when you have big volumes and need speed.

- Zhibang offers a whole line of folding cartons that can share dielines across several SKUs, so you don’t pay for every tiny size change.

- Printed corrugated boxes and mailers

- Work as outer shippers for e-commerce or as the only box.

- Handle last-mile hits but still show your branding.

- Good for subscription boxes and online orders.

- See Zhibang’s printed corrugated boxes when you want a strong logo hit with simple print.

On the factory floor you’ll hear jargon like GSM, flute profile, knife die, make-ready, and kitting labor. That’s the “black talk” where cost really hides. For example, one extra foil color means another make-ready, more waste at start-up, maybe more checking time. When you work with an OEM like Zhibang Packaging, their engineers can tune these details so your spec still looks sharp but doesn’t blow the budget.

SKU Complexity, Logistics, and Printed Corrugated Shipping Boxes

Another silent cost is SKU complexity.

If you have too many box sizes and structures, your warehouse feels it:

- more bin locations

- more training for staff to pick and pack

- more chance of “wrong box for wrong size”

- slower packing speed

A better way is to build a small family of custom apparel boxes and reuse them.

| Box type | Main use | Branding level | Ops and cost view |

|---|---|---|---|

| Rigid lid-and-base apparel gift box | High-value shirts, coats, limited drops | Very strong | Keep to a few sizes, use for hero SKUs only. |

| Collapsible magnetic gift box | Cross-border e-com, gifting | Strong | Ships flat, saves storage; ideal when warehouse space is tight. |

| Folding carton for apparel | Basics, innerwear, multi-packs | Medium to strong | High packing speed, clean shelf look, good choice for large runs. |

| Printed corrugated mailer | Online orders, subscription outfits | Medium | One or two sizes can serve many products, reduces outer-pack chaos. |

| Kraft apparel box | Eco lines, relaxed brands | Natural look | Good for “plastic free” story and simple logistics. |

Zhibang can supply all of these in one system, from collapsible gift boxes to kraft cartons and rigid sets. That makes it easier to standardize footprints while still giving marketing different “faces” to play with.

Eco-Friendly Apparel Packaging and Brand Value

Sustainability moved from “nice idea” to real buying factor. More and more shoppers look at how much plastic and mixed material sits around their new shirt.

If your boxes feel heavy, glossy and full of random foam, some people will think “this is too much”. On the other hand, a neat paper-based pack with clear recycle icons fits both brand story and retailer rules.

Eco-Friendly Paper Gift Boxes and Apparel Boxes

For apparel, eco packaging often means:

- mostly paper or board, no or low plastic

- recycled or certified fibers

- simpler coatings and water-based inks

- paperboard inserts instead of foam or blister

Zhibang already runs full eco lines like eco-friendly paper gift boxes and kraft paper gift boxes. They also build eco thinking into apparel boxes, tubes and shipping cartons.

Here’s how that plays out:

| Aspect | Plastic-heavy apparel box | Paper-based apparel box |

|---|---|---|

| After unboxing | Harder to sort, feels messy | Mostly one stream, easy to recycle |

| Brand feeling | Fancy but a bit wasteful | Modern, clean, more responsible |

| Retail acceptance | More questions from buyers | Fits “green shelf” and audit needs |

| Reuse chance | Often thrown away | Can be kept as storage or gift box |

When you work with one partner across rigid boxes, folding cartons and printed corrugated boxes, you can switch SKUs step by step into more eco-leaning structures instead of ripping everything up in one season.

OEM/ODM Custom Packaging Solutions with Zhibang Packaging

Most fashion teams don’t want to live inside print specs. They just want the box to look right, arrive on time and not kill margin.

This is where an OEM/ODM manufacturer like Zhibang Packaging is handy. Zhibang is a global supplier of wholesale custom paper packaging solutions, with ISO 9001 quality management and strict international standards. The company produces millions of units every year for apparel, cosmetics, electronics, food and other industries, and ships to more than thirty countries.

A few real advantages:

- Structure and engineering support

Zhibang’s team helps you set the dieline: board thickness, flap design, fit for the garment. This reduces crushing, returns and “box looks weird” complaints. - Color and finish control

From CMYK to metallic foil and soft-touch, everything is handled in-house. That lowers color drift and keeps your brand tones stable across runs. - Balanced spec suggestions

You might say: “We want a premium feel, but unit cost and freight must still be acceptable.” Zhibang can suggest going from full rigid to a smart premium lid and base apparel gift box with ribbon bowknot or a collapsible rigid version, so you keep the look but cut freight volume. - One-stop for several box types

You can source: - custom apparel boxes for core fashion lines

- paper gift boxes for seasonal gifting

- folding cartons for basics and accessories

- printed corrugated boxes for shipping and subscriptions

- Global supply chain fit

With export experience to North America, Europe, Australia, Japan, Korea and more, Zhibang already understands customs docs, shipping terms, and quality paperwork. That reduces risk when you scale up.

In short, they don’t just print artwork. They help you use the box as a tool for brand and for supply chain.

Practical Framework for Balancing Cost and Branding in Custom Apparel Box Design

To close, here’s a simple checklist you can run when planning your next season of custom apparel box design.

- List your “hero” products

These are the garments where unboxing really matters: sets, suits, collabs, gifting items. Give them stronger packaging like rigid gift boxes or collapsible magnet boxes. Leave lighter cartons for basics. - Limit the number of box families

Try to keep three or four key footprints across the range. Let print, sleeves and inserts create variety instead of changing structure every time. Your warehouse team will thank you alot. - Decide your sustainability level

Pick which lines go kraft and eco first. Use options like eco-friendly paper gift boxes or kraft paper gift boxes where the story fits. - Work with one strong OEM/ODM partner

If you can, let one factory handle your main paper packaging categories. A partner like Zhibang Packaging can manage design, sampling, mass production and QC under one system, with OEM/ODM customization for different brands and regions. - Measure what the box should really change

Is your main goal lower damage rate? Better reviews? Higher repeat orders? Your box should match that target. For some brands, a simple upgrade to a printed corrugated mailer is enough. For others, a full rigid gift box is the right move.

You don’t need to pick “cheap brown carton” or “crazy luxury box” for everything. The sweet spot is mixing structures and specs in a smart way, so each SKU gets the right level of branding and the right cost.

Get that balance right, and your custom apparel box stops being a cost line only. It becomes part of how you sell, how you get talked about, and how your label feels in people’s hands.