Candle Box Safety: Choosing Materials and Liners

When someone opens your candle box, you want them to feel relaxed, not worried about fire risks. Looks sell the product, but safety keeps your brand alive in the long run. That’s why material choice, liner structure, and small details in the box matter so much, especially if you run bulk orders or OEM/ODM projects.

As a custom box supplier, Zhibang Packaging helps brands, retailers, and cross-border sellers design candle packs that look high-end and behave well in real life, from warehouse to living room.

Let’s break candle box safety down in a simple, practical way.

Table of Contents

Candle Box Safety Basics for Brands

Before you think about foil stamping or ribbons, ask three questions:

- Where will people burn this candle? Bedrooms, bathrooms, spas, restaurants, gift baskets.

- What holds the flame? The candle should burn in a tested glass jar or metal tin, not in the outer box.

- What can catch fire around it? Cartons, tissue, shredded paper, foam, plastic films.

Your box should:

- Protect the candle during shipping and storage

- Support clear safety labeling

- Make it obvious that the candle must be removed from the box before lighting

That’s the baseline for any safe candle packaging system.

Candle Box Materials for Safe Candle Packaging

Rigid Candle Boxes and Paperboard Packaging

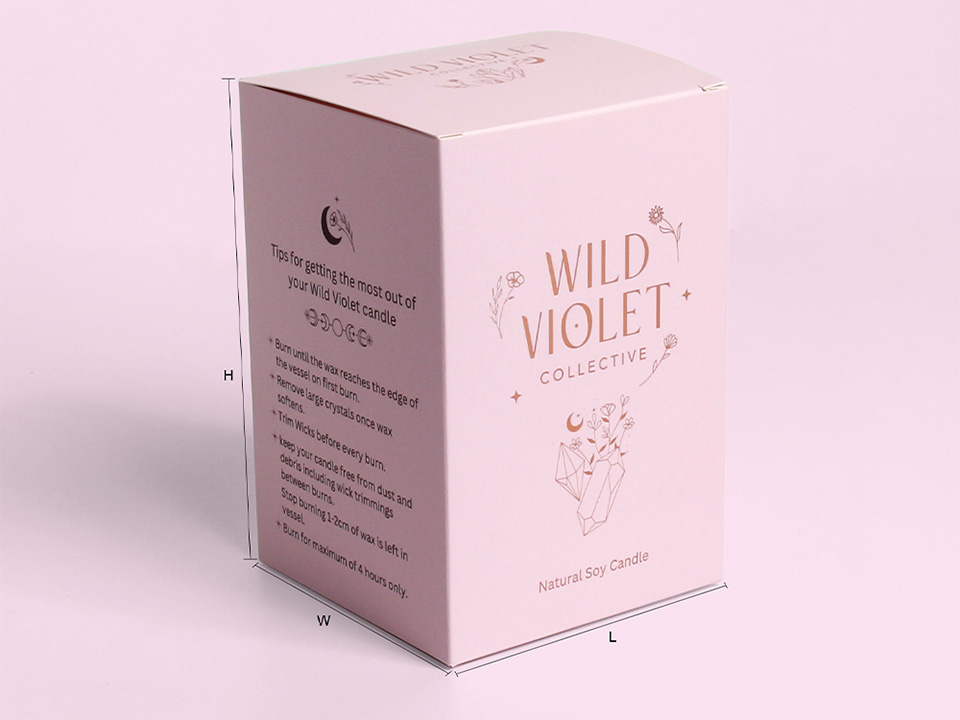

Most mid- to high-end candle brands use rigid or folding cartons as secondary packaging. These are perfect for branding, unboxing, and shelf presence.

On Zhibang’s side, typical structures include:

- Candle boxes for different jar sizes and weights

- Luxury pink rigid candle box with foam, for heavy glass candles

- Soft-touch candle gift box for premium spa or essence candles

Why brands like these materials:

- Strong enough for glass jars

- Easy to print, foil, and emboss

- Compatible with gift sets and seasonal launches

- Work well with foam, card, or pulp inserts

Safety tips in plain language:

- Treat the box as secondary packaging, not as a candle holder

- Avoid photos or usage shots that show candles burning inside the box

- Match the board weight to the candle weight to avoid collapse or cracking in transit

Corrugated Shipping Boxes for Candle Logistics

Most candles now travel through 3PLs, couriers, and cross-border shipping. That’s why outer mailers and master cartons matter.

Using strong printed corrugated boxes helps you:

- Pass basic drop tests

- Protect fragile jars and lids

- Stack pallets safely without crushing inner packs

Corrugated still burns, so it’s not part of “in-use safety,” but it is part of supply-chain safety. A broken jar that leaks hot wax is also a risk, so good corrugated design reduces that failure rate.

Rectangular and Clamshell Candle Jar Boxes

Different structures behave differently:

- Rectangular cardboard candle jar boxes are simple, efficient, and easy to palletize

- A clamshell candle jar box gives a more premium “book-style” opening

- A square rigid candle jar box is great when you have heavier jars and want strong side walls

All three can be safe, as long as the structure:

- Holds the jar tight

- Leaves space for warning labels

- Guides the user to lift the jar out before lighting

Candle Box Liners and Inserts for Candle Protection

The insert is where a lot of real safety work gets done, even though the end user might never think about it.

EVA Foam Inserts for Candle Box Packaging

Foam inserts are common in higher-end packs and wholesale gift sets. They:

- Lock jars or tins in place

- Absorb impact during transport

- Add a premium, “fitted” look inside the box

Zhibang often combines EVA foam with rigid boxes, just like in many of our candle and paper gift boxes.

Safety points:

- Foam is still a flammable material

- Make the cavity tight enough that the jar doesn’t knock around (fewer cracks, fewer leaks)

- Layout should make it natural for the customer to pull out the jar, not burn it while it’s still sitting in foam

In project language, this is part of your packaging engineering: matching cavity size, jar diameter, and foam thickness to the candle weight.

Paper and Pulp Inserts for Eco-Friendly Candle Packaging

If your brand pushes sustainability, molded pulp or cardboard inserts are a good alternative:

- Better story for eco-minded customers

- Easier to recycle with the main board

- Lighter weight for freight and carbon footprint

These still need the same basic rules:

- They are not a heat shield

- They should not be used as a “tray” for burning

- They must give enough protection in transit so you don’t see high breakage rates at the DC or store level

Decorative Fillers and Shredded Paper in Candle Gift Sets

Gift sets move fast during holiday peaks. Shredded paper, tissue, and wood wool help:

- Fill voids in big presentation boxes

- Stabilize mixed sets (candle + mug + chocolate, for example)

- Add a “wow” effect when the lid opens

But from a safety angle, they’re pure fuel. So you:

- Keep filler below the jar rim

- Use a simple instruction card to tell users to remove loose shred before lighting

- Avoid photography that shows a burning candle surrounded by filler

These may sound like small details, but they help you avoid awkward customer service tickets later.

Plastic Liners and Barrier Films for Candle Packaging

Sometimes you need a barrier against fragrance oil, wax, or moisture. Thin plastic liners and coated papers can:

- Protect the inside wall of the box

- Stop oil rings forming on the base

- Keep branding surfaces cleaner

Good use cases:

- Under the jar, as a discreet disc or film

- As part of a label or tamper-evident seal

Bad use cases:

- Anything close to the flame

- Films that might soften, droop, or melt near heat

If you already work with child-resistant packaging or marijuana packaging, you know regulators don’t like unsafe plastics around heat. The same mindset applies to candles.

Labeling and Compliance for Candle Packaging Safety

Safe structure is one part. Safe information is the other.

Your candle box should leave room for:

- “Burn within sight” and similar core warnings

- Icons for fire risk, flammables, kids and pets

- Multi-language text for export markets

From a packaging-buyer perspective, this matters because:

- Big retailers want clear compliance panels

- Cross-border sellers need space for extra labels or local stickers

- Brand teams still need zone for logo, scent name, and ingredients

When we design candle boxes at Zhibang Packaging, we treat warning space as a real requirement, not leftover space.

Real-World Candle Packaging Scenarios

To make it concrete, here are three typical cases.

1. Beauty brand spa candle line

- Wants soft-touch rigid box, blind embossing, luxury foam insert

- Ships through 3PL and online platforms

- Setup: rigid jar + luxury pink rigid candle box + corrugated master carton

- Safety win: tight EVA cavity, clear warning panel, unboxing flow that forces the jar out of the box

2. Gift company seasonal hamper

- Candle + chocolates + small accessories in one box

- Uses shredded paper and dividers as void fill

- Setup: jar candle box nested inside a larger gift pack

- Safety win: printed note asking users to remove loose paper before lighting, cavity design that stops the jar tipping over

3. THC/CBD or wellness brand

- Already follows strict rules for concentrates and oils

- Wants candle line that fits same “safety first” story

- Setup: child-resistant outer pack plus safe candle jar box

- Safety win: shared icon language across oils, edibles, and candles, strong box structure borrowed from regulated cannabis packaging SKUs

In all three, the candle burns in the container. The box and liner handle branding, logistics, and unboxing.

Candle Box Materials and Liners: Quick Reference Table

| Component | Recommended materials | Main safety role | Key risks if done wrong |

|---|---|---|---|

| Primary container | Heat-resistant glass jar, metal tin | Holds flame and molten wax | Thin glass cracking, soft metal deforming |

| Retail candle box | Rigid board, folding carton | Branding, shelf impact, secondary protection | Used as a “holder” while candle burns |

| Shipping carton | Corrugated cardboard | Protection in transit, pallet stability | Broken jars, wax leaks, crushed units |

| Inserts | EVA foam, cardboard, pulp | Positioning, impact protection | Treated as burn surface, loose fit causing damage |

| Decorative filler | Tissue, shred, wood wool | Gift feel, void fill in hampers | Left around flame, easy ignition |

| Liners/barriers | Plastic liner, coated paper | Oil and wax barrier, clean look | Melting near heat, giving fake sense of fire safety |

How Zhibang Supports Candle Box Safety

If you’re a retailer, brand owner, or trading company, you’re probably juggling:

- MOQ pressure and timeline

- On-shelf impact for candles

- E-commerce ship-test performance

- Compliance, especially for export

With experience in candle boxes and a wide range of custom structures, Zhibang Packaging can help you lock in:

- The right board grade for your jar weight

- Insert options that balance safety, cost, and eco story

- Layout that keeps warning text and branding working together

When your candle box is safe, clear, and good-looking, your customer simply lights the wick, enjoys the scent, and never thinks about the packaging again—and that’s exactly what you want.