Luxury Jewelry Box Packaging: Combining Beauty with Protection

Luxury jewelry might be tiny, but the box holding it carries the whole story. It needs to look premium, feel right, and shield delicate pieces through shipping, storage, and unboxing. When someone opens a jewelry box, the moment should feel smooth, intentional, and a bit emotional.

Brands today want packaging that blends that premium vibe with rock-solid structure — and that’s where expert manufacturers like Zhibang Packaging shine. With global production capacity, ISO-certified systems, and deep experience in custom paper packaging solutions, they show how beauty and protection can live in one box.

The Power of First Impressions

The first “second” still decides the customer’s mood. Texture, weight, surface feel — these micro-details create trust fast.

Surface Choices That People Actually Notice

Jewelry buyers respond well to:

- soft-touch finishes

- linen-like wraps

- smooth corners

- clean color consistency

- sharp foil logos

These details protect what we call presentation integrity — meaning the box never looks sloppy or cheap. Inside factories, technicians measure things like wrap tension, glue uniformity, and color drift to keep consistency batch after batch.

Features That Shape Luxury Feel

| Feature | Why It Matters | Best Scenarios |

|---|---|---|

| Soft-touch lamination | Smooth + warm | Ring and necklace boxes |

| Deboss/emboss | Adds depth | Boutique collections |

| Foil stamping | Signals premium | Anniversary editions |

| Linen-textured paper | Old-money vibe | Heritage sets |

Anyone wanting long-term consistency can explore luxury rigid boxes designed by Zhibang Packaging — they stay stable across mass runs.

Protection: The Unseen Engineering Behind Every Box

Pretty boxes matter, but protection is the secret engine. It prevents:

- crushed corners

- cracked lids

- rattling jewelry

- customer complaints

Rigid Construction for Strength

Rigid boxes lead the category because they resist:

- compression

- twisting

- impact

- deformation

Online sellers especially rely on them because shipping is rough.

Fitment (Insert) Engineering

The inner tray is where most brands struggle. If the insert shifts, everything shifts.

Insert Materials & Their Roles

| Insert Material | Protection Level | Why Brands Choose It |

|---|---|---|

| EVA foam | Very high | Holds pieces firmly |

| Velvet-wrapped foam | Gentle | Ideal for polished metals |

| Pulp trays | Eco + lightweight | Zero-plastic collections |

| Molded paperboard | Balanced | Fully recyclable |

Zhibang Packaging’s custom jewelry box manufacturing uses precision die-cutting to fix common insert issues like looseness, rattling, or uneven padding.

Sustainability Without Losing Luxury

Eco-friendly packaging is now standard, even for jewelry. Customers ask about recyclability, plastic reduction, and reusability.

Manufacturers respond with:

- FSC-certified boards

- recycled grayboard

- water-based coatings

- paper-based inserts

- mono-material structures

Eco Material Comparison

| Material | Eco Score | Brand Message |

|---|---|---|

| Recycled board | High | Responsible |

| Kraft paper | High | Natural look |

| Pulp trays | Very high | Zero-plastic |

| Water-based coatings | Medium | Clean + modern |

Brands planning greener packaging can explore eco-friendly packaging options offered through Zhibang Packaging’s global channels.

Finishing Techniques That Drive Aesthetic Value

Finishing is where luxury becomes visual. It creates emotion and instantly sets the tone.

Popular High-End Finishes

- foil stamping

- embossing/debossing

- spot UV gloss

- fabric-wrapped rigid boards

- matte coatings

- satin lamination

Inside production lines, technicians guard against foil misalignment, lamination bubbles, and surface scratches — the usual pain points. With partners experienced in premium rigid gift box production, brands avoid these quality dips.

Customization: Now a Must-Have for Jewelry Brands

Minimalist boxes and generic sizes no longer work. Jewelry brands need designs tailored to their unboxing moments and brand identity.

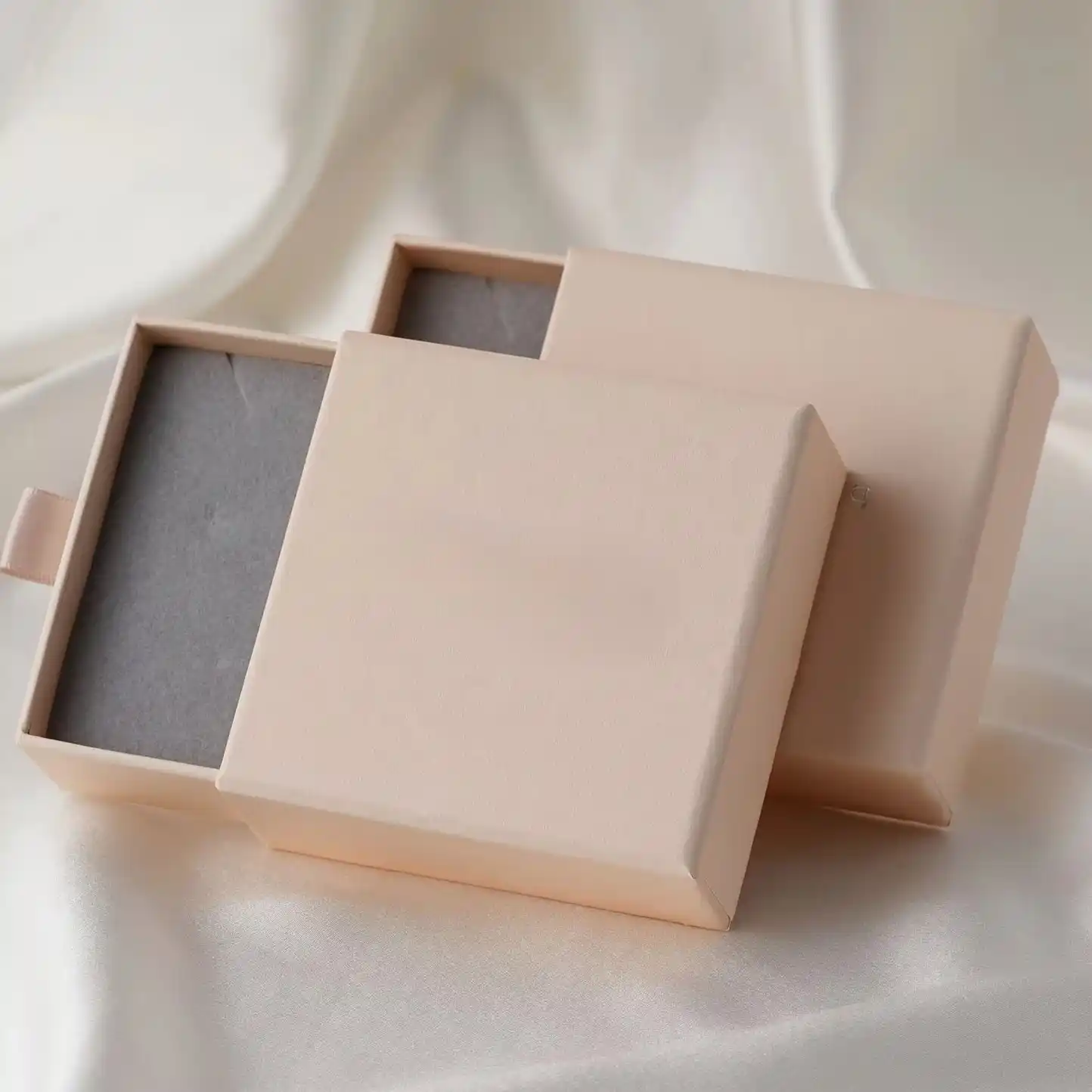

Trending Custom Structures

- drawer-style boxes

- magnetic-closing boxes

- ribbon-pull systems

- foldable rigid boxes

- multi-layer sets

- sculpted inserts

Zhibang Packaging’s OEM/ODM custom packaging services let brands tweak structures, textures, and finishes freely — crucial for scaling across global markets.

Real Industry Pain Points (and How Packaging Solves Them)

| Pain Point | Industry Term | Solution | Comes From |

|---|---|---|---|

| Crushed corners | Edge compression | Thick board + reinforced edges | Rigid-box engineering |

| Loose jewelry | Insert shifting | Custom EVA cutouts | Fitment design |

| Logo mismatch | Color drift | Pantone-calibrated printing | ISO QC |

| Freight too high | Volume inefficiency | Fold-flat rigid boxes | Structural redesign |

| Surface scratches | Abrasion marks | Soft-touch lamination | Finishing line |

| Weak closures | Magnet fatigue | High-pull magnets | Closure testing |

These are daily issues for brands shipping globally. With a strong supplier using global paper packaging manufacturing standards, consistency becomes much easier.

Scenarios Where Beauty + Protection Work Together

Boutique Display

Boxes must stack neatly and stay color-consistent. Matte laminations + foil accents achieve a premium shelf look.

E-Commerce Shipping

Multiple warehouses, long routes, rough handling — rigid boards and stable inserts prevent returns.

Gift Packaging

Customers want a “moment.” Drawer styles, ribbon pulls, and soft-touch surfaces create that feel.

High-Value Jewelry

Scratch-free interiors, dust-free assembly, and tight tolerances are key. Zhibang Packaging specializes in premium jewelry box solutions used across international markets.

Why Brands Choose Zhibang Packaging

Global brands rely on Zhibang because the company offers:

- ISO 9001 quality control

- mass-production stability

- precise color matching

- custom structures

- high-end finishing options

- eco packaging solutions

- global delivery

- OEM/ODM flexibility

Brands needing long-term consistency benefit from their custom paper packaging manufacturing across multiple product lines.

What Really Matters in the End

To blend beauty with protection in jewelry packaging:

- Use strong board material

Shape retention is key. - Engineer the inserts properly

No movement, no scratches. - Match finishing to brand identity

Foil, matte, linen — each signals a different personality. - Add eco elements

Modern consumers notice. - Test before scaling

Drop tests, color checks, magnet strength — all crucial. - Work with a global supplier

This controls consistency across countries.

Brands exploring upgrades can browse Zhibang’s custom packaging solutions for global buyers — built for reliability and scale.