The Time Battlefield Of Packaging Box Proofing: From Efficiency Revolution To Reconstruction Of Brand Value

Abstract

Proofing is where brands place their first bet against time. In this high-velocity arena, a sample is more than a miniature of the final box—it’s a negotiation between design intent, manufacturability, sustainability, and risk. When proofing is slow, launches stall and stories go silent; when it’s smart, brands compress calendars, stabilize quality, and turn speed into trust. This article maps the proofing battlefield: why cycles stretch, how digital tools fold time, where processes can be rewired, how machine vision claws back defects before they spread, and how circular systems turn samples from waste into assets. Throughout, we connect strategy to real production contexts—rigid sets, folding cartons, corrugated mailers, tubes, displays—so your next proof moves faster and lands truer.

Explore our homepage to see how these strategies translate into box styles, materials, and finishes at scale.

Table of Contents

1. The industry code of the proofing cycle: the game between complexity and efficiency

Multi-variable complexity in real projects

Proofing time expands with every variable you add: substrate families (rigid board, duplex, kraft), converting paths (die-cut, crease, fold, glue), and finishes (foil, UV, lamination). Each variable multiplies decision points—tolerances, fiber direction, ink holdout, glue chemistry—and each decision point invites rework. That’s why a “simple” lid-and-base can outpace a fancy drawer box if the former hides hidden risks (tight tolerances, soft-touch film, deep cavities) while the latter is well-engineered.

Bottlenecks you can actually control

- Ambiguous dielines: unclear crease/knife layers force CNC or laser cutters to slow down for interpretation.

- Color ambiguity: brand palettes without substrate-specific targets trigger avoidable rounds of on-press tuning.

- Late assembly tests: inserts, trays, and accessories validated after print turn “unknowns” into rebuilds.

Pair complexity with the right proofing path

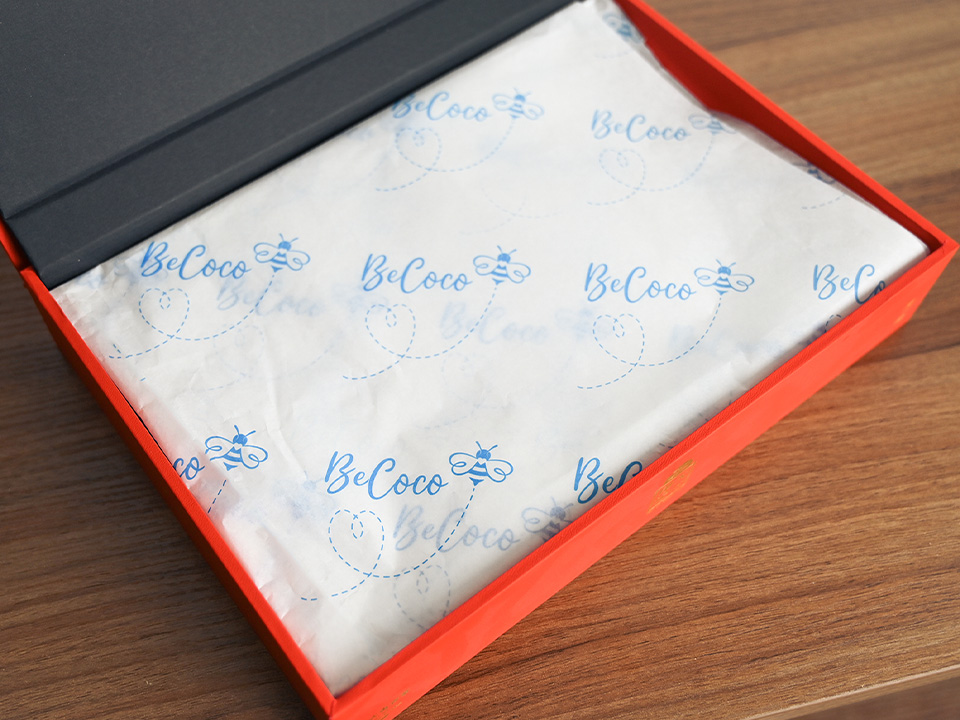

- For rigid gift boxes and high-touch unboxing, prioritize early structural samples to lock fit and feel. A quick tour of practical formats starts with paper gift boxes and expands into modular accessories.

- For folding cartons, front-load die and fold trials; see how our folding cartons workflows align artwork with crease behavior.

- For corrugated mailers, validate compression and closure ergonomics before color—our printed corrugated boxes library shows why.

2. Smart proofing revolution: Digital technology reconstructs production paradigm

Digital twins for boxes

A packaging digital twin—dieline + substrate profile + finish stack—lets teams simulate fold strength, hinge fatigue, tear paths, and panel bowing before any board is cut. When your CAD carries flute or board caliper metadata, you’re not guessing; you’re predicting.

Color management as a system, not a stop

Spectral targets attached to each substrate remove the “looks right under this light” trap. Device-link profiles and substrate-specific curves allow proofs to travel accurately across offset, digital, and flexo paths. The result is fewer loops between design, prepress, and press checks—speed born from agreement.

Automation bridges the last mile

- Parametric dielines—change a bottle diameter and the insert breathes with it.

- Preflight robots—font embedding, overprint warnings, bleed/quiet-zone checks, all before human review.

- Digital prototyping—laser-cut and digitally print one-offs for fast haptic feedback without blocking presses.

See how these principles connect across form factors in our products showcase, from telescoping lids to magnetic closures.

3. Process reengineering strategy: paradigm shift from serial to parallel

From “throw-it-over” to cross-functional pods

Serial handoffs (design → prepress → sampling → procurement → quality) create idle time. Cross-functional pods compress cycles by aligning decisions in the same window: structural choices, palette mapping, adhesive selection, and insert tolerances are set together, not sequentially.

Parallelization patterns that work

- DFM workshop at concept stage: designers, engineers, and buyers align on feasible specs and ready-to-source materials.

- Two-stream proofing: run structural and color proofs in parallel. Approve fit first, color second, but don’t wait to start the other.

- Gate checklists: each phase exits with a clean contract—approved dieline version, substrate code, finish stack, and test notes—so downstream tasks don’t re-litigate upstream decisions.

Templates and platforms accelerate learning

Reusable BOMs and dieline families for common SKUs (fragrance, candles, electronics) remove reinvented wheels. Browse examples in cardboard displays to see how display architecture benefits from templated strength and access angles, and in paper tube packaging to observe parametric diameter/height systems.

4. Quality control revolution: millimeter-level competition of machine vision

Vision systems as proofing copilots

Machine vision brings “millimeter-level” to life: camera arrays assess crease depth uniformity, detect edge fray, measure panel gaps, and flag skew before a batch becomes “finished defects.” On print, inline scanners monitor registration drift, trapping, and ΔE color variance across the sheet.

Close the loop with data

- Structural metrics: fold angle, magnet alignment, tray insertion force.

- Print metrics: density, gray balance, halftone integrity.

- Assembly metrics: glue line width, cure completeness, lid-base flushness.

When vision and SPC feed back into the CAD and prepress libraries, each proof improves the next. For workflows involving retail units and instruction sets, our printing services integrate manuals, inserts, and labels into the same control loop for a consistent pack-out experience.

5. Circular Proofing System: Implementation of Sustainable Strategy

Design proofs to live a second life

Treat proofs as assets, not expendables. Use standardized cores, removable magnets, and reusable inserts so components reenter sampling pools. Prioritize mono-material pathways or disassemblable constructions to simplify returns and recycling.

Material choices that support circularity

- Recycled corrugate for early form-fit checks, saving premium rigid board for the final lap.

- Modular tubes where body and cap are reusable across diameters—our paper tube packaging shows how footprint families cut waste.

- Child-resistant mechanisms designed for longevity in regulated categories; see our child-resistant packaging pathways for compliant reusability without redesigning the shell each time.

Proof once, deploy many

Lock color and structure libraries, then roll them into families: hero sizes, seasonal variants, and channel-specific SKUs. This “platform mindset” is equally applicable to paper gift boxes and to velocity-driven cartons under folding cartons, ensuring consistency and speed across collections.

Summary

On the time battlefield of packaging box proofing, speed isn’t a sprint; it’s compound interest on good systems. Complexity doesn’t have to mean delay when digital twins make structures predictable, color behaves as data, and automation guards against rework. Parallel pods replace linear queues, and machine vision narrows tolerances until quality stops being a surprise. Finally, circular proofing reframes samples as reusable, data-rich assets. If you’re launching a premium rigid set, scaling a corrugated e-commerce program, or building a tube-based brand system, the same law applies: shorten feedback loops, standardize decisions, and let proofing become your brand’s first, fastest act of reliability.

Ready to translate these ideas into a live project? Start on our homepage, explore category solutions in paper gift boxes, folding cartons, printed corrugated boxes, cardboard displays, paper tube packaging, browse the full products lineup, and coordinate integrated print assets through our printing services.