How can secondary packaging of nutritional supplements improve brand competitiveness and consumer trust

How can secondary packaging of nutritional supplements improve brand competitiveness and consumer trust

Abstract

In the nutritional supplement market, secondary packaging, as the first touchpoint between products and consumers, has evolved from a simple outer layer of protection to a core carrier of brand strategy. This paper analyzes the role of secondary packaging in four dimensions: protective performance, regulatory compliance, brand value delivery, and sustainable innovation, and combines industry trends and cases to demonstrate its key impact on market competitiveness. Special attention is paid to the material safety and functional design of food-grade packaging boxes to provide a scientific basis for brands to optimize packaging strategies.

1. Protective barrier: from transportation safety to active ingredient preservation

The primary function of secondary packaging is to build a multi-protection system. Studies have shown that nutritional supplements are susceptible to factors such as light, humidity, and collision during circulation, resulting in degradation or contamination of active ingredients. For example, although an Australian brand uses glass bottles for environmental protection, the breakage rate is as high as 5% due to insufficient secondary packaging buffering, which increases safety hazards. The optimized folding carton can block 99% of ultraviolet rays and absorb transportation vibrations through its compression-resistant structure (data confirms that compression resistance is increased by 30%) and light-proof coating (such as the light-proof bottle design mentioned on the website [6]). Food-grade packaging boxes must pass ISO 22000 certification to ensure that the materials are non-toxic and migrate, especially the stability test of fat-soluble vitamins (such as vitamin D3).

2. Compliance carrier: a passport to the global market

Secondary packaging is a standardized presentation platform for regulatory information. The EU Nutrition and Health Claims Regulation (NHCR) and the US FDA labeling guidelines both require the readability and accuracy of information such as ingredient lists, allergens, and NRV values (nutritional reference values). For example, the WONDERLAB double bottle clearly conveys the scientific ratio of B vitamins with a content of 150% of NRV through the 12 vitamins labeled on the frosted bottle, avoiding the compliance risk of a Japanese brand being sued by consumers for having too small fonts. Food-grade packaging boxes must also comply with material safety standards such as GB 4806.1-2016, such as using water-based ink printing to avoid heavy metal residues.

3. Brand narrative: from shelf recognition to emotional resonance

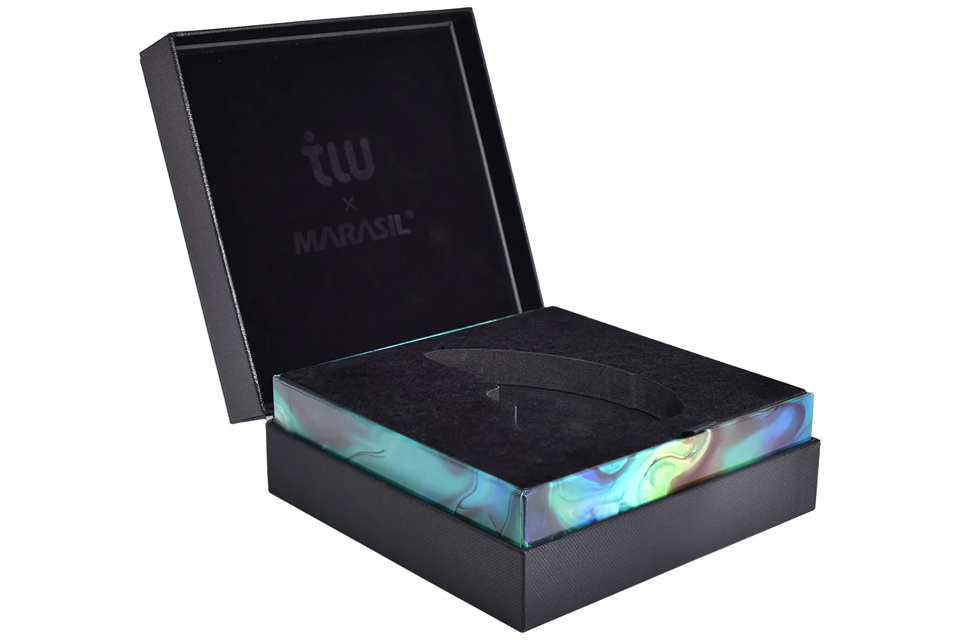

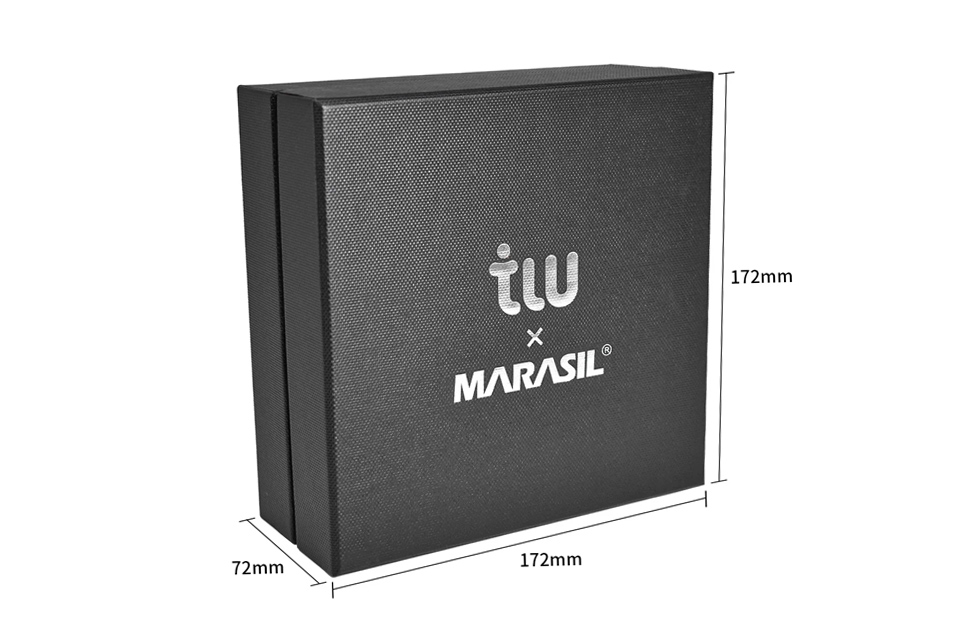

Secondary packaging is a silent "brand billboard". The "sticky note" packaging designed by Lingdan Creative for PANACEASPY transforms daily nutrition plans into interactive stickers that can be torn off, increasing the repurchase rate by 23%. Color psychology research shows that green packaging is associated with "natural" cognition (such as the growing trend of plant-based supplements on the website [7]), while the metal texture conveys a sense of high-end technology. Food-grade packaging boxes can be designed through embossing processes and openable windows. For example, a certain children's zinc supplement uses an animal-shaped card slot, which not only enhances the childlike appeal, but also solves the problem of standing stability, achieving a balance between function and aesthetics.

4. Green Revolution: The consumer driving force of sustainable packaging

Environmental protection attributes have become a competitive barrier for secondary packaging. According to Future Market Insights data, 67% of consumers are willing to pay a premium for sustainable packaging. Innovation cases include:

- Material innovation: Use FSC-certified paper boxes + PLA biodegradable film to replace traditional plastics, reducing carbon footprint by 40%;

- Structural optimization: The foldable design reduces the packaging volume by 50% and reduces logistics energy consumption;

- Circular system: such as the "empty box recycling program" in cooperation with Terracycle, which improves the brand's ESG score. Food-grade packaging boxes need to balance environmental protection and barrier properties, such as adding bamboo fiber to enhance the tear resistance of the material, while ensuring food safety through GRAS certification.

Summary

Secondary packaging has surpassed the role of "container" and has become a strategic tool for nutritional supplement brands to build a market moat. From protective design that ensures the stability of biological active ingredients, to scenario-based innovation that fits personalized consumption, to sustainable practices that lead industry change, its value chain runs through the entire product life cycle. Brands need to work with suppliers with food-grade packaging R&D capabilities (such as ISO 15378 certified factories) to transform secondary packaging into a "quality commitment" that consumers trust, and achieve differentiation in the fierce competition.

References

- Future Market Insights. (2024). Global Weight Management Supplement Market Report.

- Beijing Lingdan Creative. (2024). Case Study of Sticky Note Nutrition Packaging Design.

- National Health Commission of China. (2023). National Food Safety Standard - General Safety Requirements for Food Contact Materials and Products (GB 4806.1-2023).

- Nutritional Supplement Evaluation Network. (2025). Children's Nutrition Packaging Stability Optimization Report.